Proven strength for heavy and oversized loads

Engineered for conventional heavy transport

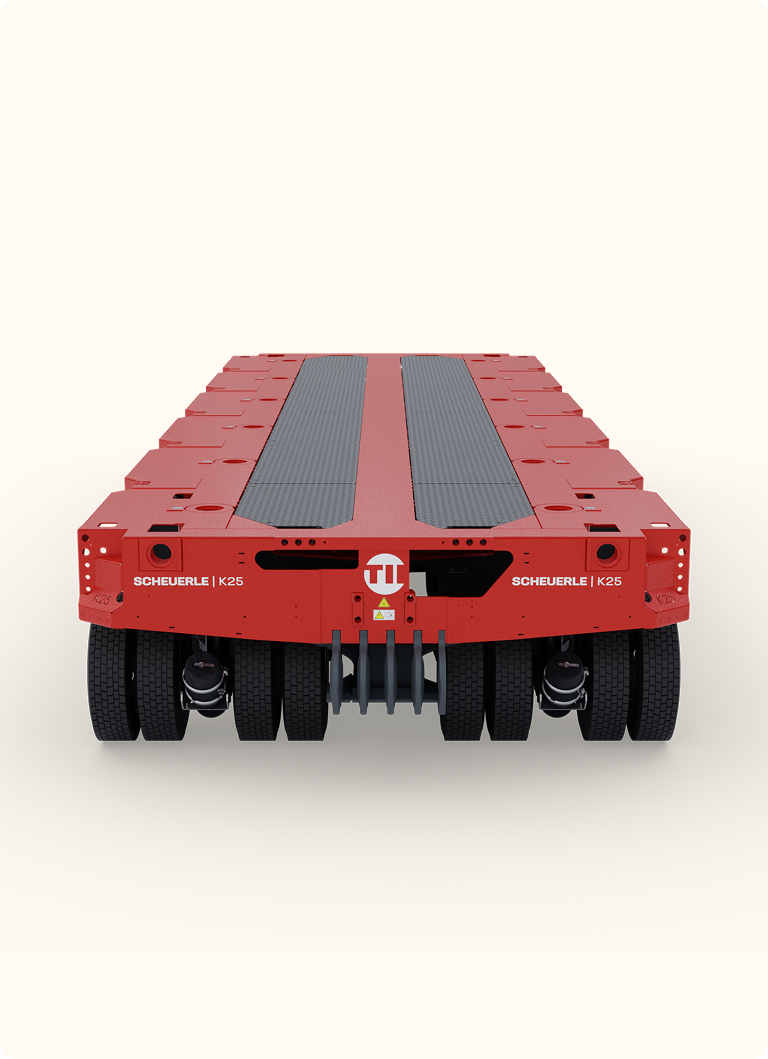

K25 heavy transport system

The K25 conventional heavy transport system is engineered to handle heavy and oversized loads with maximum stability and control. Its robust design and flexible configurations make it a reliable solution for demanding transport operations across industrial, infrastructure and energy projects.

Modular design and scalability

The K25 system consists of modular axle lines that can be combined to match the exact weight and dimensions of the load. This scalability allows transport configurations to be tailored to each project, ensuring optimal load distribution and operational safety.

High load capacity and structural strength

Built for heavy-duty applications, K25 transporters feature a strong frame construction designed to carry extreme loads. The structural strength of the system ensures stability during long-distance transport, even under challenging road and site conditions.

Steering and manoeuvrability

The K25 system offers controlled steering options that enable accurate manoeuvring on construction sites and along transport routes. This makes it possible to navigate bends, confined spaces and complex site layouts with confidence and precision.

Suspension and axle compensation

Advanced suspension and axle compensation ensure even load distribution across all axle lines. This reduces stress on the transport system and the road surface, improves stability and enhances safety during transport over uneven terrain.

CONVENTIONAL MODULAR TRANSPORT

The K25 ensures stability under extreme conventional loads

60 T

Axle load

TRACTOR-PULLED

CONVENTIONAL OPERATION

600 mm

Axle compensation

Brands we support

conventional transport Solutions from Leading Manufacturers

CONVENTIONAL MODULAR TRANSPORT

Move heavy loads. Safely. Predictably

Fall leveling

Axle compensation

Slope adjustment

Qu0026A

Frequently asked questions

Can the K25 be combined with other modular transport systems?

Yes, the K25 system can be integrated with other modular transport components to create tailored transport configurations. This flexibility allows the system to be adapted to different load dimensions, weights and project requirements.

How does the K25 maintain stability on uneven terrain or slopes?

The K25 is equipped with advanced suspension and axle compensation systems that distribute the load evenly across all axle lines. This ensures stability on uneven terrain or slopes, reduces stress on the structure and improves overall transport safety.

What is the difference between a K25 conventional system and an SPMT?

The main difference lies in propulsion and application. An SPMT is self-propelled and highly manoeuvrable, making it ideal for confined spaces and precise positioning. The K25 is a conventional, towed transport system, designed for long-distance transport and situations where controlled, road-based transport is more efficient and cost-effective.

When should a conventional K25 be chosen instead of an SPMT?

A K25 is the preferred choice when loads need to be transported over longer distances, on public roads, or when site conditions allow for conventional towing. It is especially suitable when extreme manoeuvrability is not required and when transport efficiency and capacity are the primary considerations.

Rent a Conventional trailer

Leave your details and we will get back to you shortly

00:00

/

00:00